| Issue 11 |

Andrew Garrad started by recollecting that when he left Oxford in 1975, his tutor David Clarke had advised him to "give up this silly wind energy idea". He was very glad that he had not taken this advice! His firm of wind power consultants (Garrad Hassan) was now a world-wide organisation employing 800 people.

He began with a little history of wind power since about 1940. In 1941 a 1.5 MW turbine was erected at Grandpa's Knob, Vermont. Remarkably, the aerodynamic and structural design respectively were the responsibility of two names well known to engineers, Von Karman and Timoshenko. In 1946 NASA, or NACA as it was then, had designed, but did not build, a 7.5 MW turbine with a d.c. generator and a synchronous converter to turn the output to a.c. A "no-problem" design they called it! The designers had envisaged a complete wind farm.

One of Andrew's early consulting jobs, in 1984, had been concerned with a set of turbines that had extruded polyester blades. They were too floppy, and were giving trouble, going through a resonance and hence falling off. His advice was to replace them with wooden blades, which was done. Six months later he enquired how they were faring. The blades were fine, but the towers were all broken! This had taught him a valuable lesson - these are coupled systems and you have to model everything.

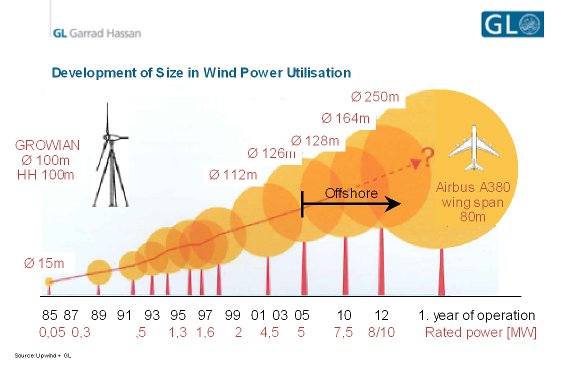

He had now spent about 30 years in this business, and had had a great deal of fun out of it. The size of turbine had increased phenomenally over that time, and they were still getting bigger. He illustrated this with a slide showing successive specimens built over that time, from 15 m diameter rotors generating 50 kW in 1980, to 164 m diameter ones and 8-10 MW in 2012. By comparison, the wingspan of an Airbus A380 is 80 m (Figure 1 below). In fact turbines need to get even bigger. 250 m diameter ones are in prospect. But they need to get better too. Andrew claimed that these were now the largest rotating machines in the world, though he admitted that a nuclear physicist he had been talking to recently made the same claim for the Large Hadron Collider!

|

| Figure 1 |

He invited the audience to estimate how much air per second passed through a 110 m diameter turbine when the wind speed through it was 10 m/s. The audience's mental arithmetic was evidently not fast enough for this. The answer is 116 tonnes.

And they have to be designed for long life, 15-20 years and 108 fatigue cycles, which is on the edge of existing knowledge about the composite materials used. In contrast, the operating life of a typical car is about nine months, while a lorry may manage three years.

The scale of wind power use has been much increased over the last five years since its adoption by China. They have built a 3.8 GW wind farm, and 10 GW ones are being planned. To put these figures in context, the total generation capacity in the UK (all sources, not just wind) is 65 GW. These Chinese ones are well inland, towards the North-West, but they are also planning them in the inter-tidal zones to the East, and true offshore ones in the South-East. The Chinese have a different attitude to innovation from Europeans. In Europe, the most dreaded stigma is failure, so we spend years testing prototypes before committing ourselves to anything large-scale. In China, the worst stigma is inactivity. "Do something!" The other difference is in the cost of employing people, so the Chinese will commit far more people than we would to manage a wind farm. But then, they are not short of people. In 2010, about half of the world's new installations were in China, about 15 GW's worth.

There is no practical limit to the amount of wind power available, but the challenge is to integrate it with the national supply grids. Europe is now generating about 1% of its wind power offshore. We could perhaps get it up to 10%. But eight offshore farms, each 100 km x 100 km, could supply all of the EU's electricity demand. Alternatively we could perhaps generate it in the empty spaces of North Africa, but would then have to create a transmission system to get it to Europe. These are all political decisions, but their consequences will be seen over the next 50 years. Politicians' horizons seem to be limited to the time of the next election.

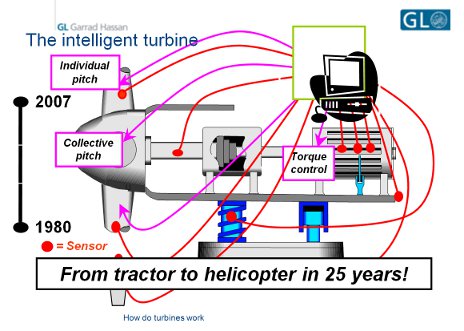

Early wind turbines were quite simple technically, fixed pitch blades driving induction generators at near-constant speed through three-stage gearboxes. Then came torque and collective pitch control, variable-speed generation and electronic frequency conversion. More recently, each blade has been given its own pitch control, which can be used to reduce the loads on them and hence extend their fatigue life. Complexity has developed from something like that of a farm tractor, to more like that of a helicopter. So the nerve centre of the modern turbine is its control system (Figure 2 below).

|

| Figure 2 |

Turbines installed over the last few years have had glass- or carbon-fibre epoxy blades, and doubly-fed induction generators to allow for speed variation. But in the most recent designs generators are of the permanent-magnet type, and the gearbox may make do with two stages rather than three, and hence be more efficient. A German firm has built a turbine with direct drive (no gearbox) driving a rather large slow-speed generator. But the rare earths used to make permanent magnets come almost all from China, and the demand for them has pushed their price up fivefold. So a possible problem is lurking there. Maybe high-temperature superconductors will come in some day. Developments in power electronics have been of great value to the industry.

It is often alleged that in the UK at least wind power is intermittent and unpredictable. It certainly varies with the wind strength, but Andrew thought that "intermittent" meant something which was either there or not there. This was not the case. On predictability, his firm had shown that it was possible to predict with good accuracy what would be available 24 hours ahead. It should therefore be possible to arrange for the optimum combination of wind power and conventional forms of generation, which themselves are liable to their own fluctuations. A sudden loss of two 660 MW conventional sets was recognised as a feasible scenario. His aim was "to make wind farms look conventional".

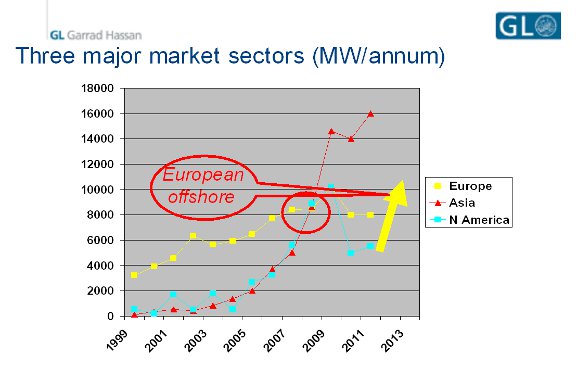

There are three main markets for wind energy: Europe, N. America and Asia, which means basically China. Around 2000, Europe was in the lead, with N. America and China coming up quite fast from a low level. In 2009, all three were equal, installing about 9000 MW/year, but since then Asia has shot ahead (Figure 3). All three faltered a bit in the subsequent financial crisis, but Asia is now well ahead at 16,000 MW/year, as against Europe's 8000 and N. America's 6000. China is now competing to sell turbines in the European market.

|

| Figure 3 |

Onshore turbines suffer from the constraint of having to be "good neighbours". Offshore the constraints are more of an engineering nature. For instance, onshore turbines are expected to have three blades, because that "looks right". Three blades are indeed more "efficient" than two, but two blades might be more "cost-effective". And onshore turbines have to have the blades upwind of the tower, otherwise there is a "thud" as the lower blade passes behind the tower. He thought that in this field we were only just starting, and that in ten years' time, offshore turbines might look quite different from onshore ones. The main difficulty of course lies in the tower structure. Some early offshore towers had been built on a simple gravity concrete foundation. Monopoles and tripods have been used, and suction buckets to pull their legs into the sea bed were being investigated. It has been shown that one can have the whole structure just floating. He showed slides both of an otherwise conventional turbine by Norsk-Hydro held up by a floating, though deeply submerged, extension to the tower, and of a proposal for a vertical-axis turbine also floating (easier here, since the height was quite low).

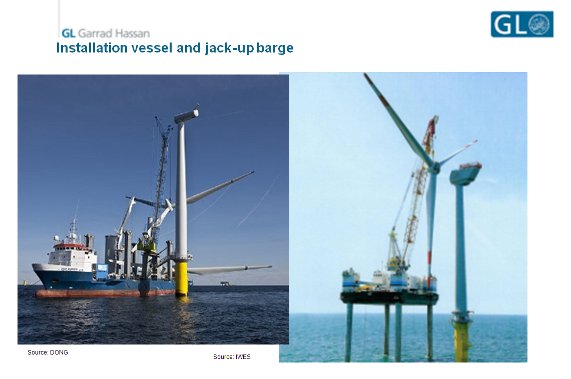

Apart from the electrical connection to the mainland, the major problems with offshore turbines are how to erect them in the first place, and how to get access subsequently for maintenance. Onshore turbines have demonstrated an availability of better than 97% - to match this offshore will be a challenge. The failure of a £20 fuse could lose one £1 m in lost generation if it could not be replaced for months because of the weather. A substantial and money-spinning industry is growing up to supply equipment for these two purposes. Some of it was illustrated (Figure 4). Erection needs very long cranes, such as have been developed for the offshore oil industry. They can be mounted either on vessels or on jack-up platforms. The latter, unlike the former, are not subject to wave-induced motion. For floating vessels this can be compensated hydraulically, and we were shown a short film of this method being used to gain access to an oil platform. Another way of getting such access is by helicopter, and some slides of this revealed a powerful argument for having a two-bladed rotor (not one mentioned by the speaker!). It can be stopped in the horizontal position, making it much safer for the helicopter to get close above the tower-top.

|

| Figure 4 |

The attitude of the transmission system operators (e.g. National Grid) towards wind power had gone through three stages: ridicule initially, then animosity (they did not want these machines on their grid), and more recently, in some areas at least, cooperation. The three considerations which had brought them round were: environmental change; the security of a UK-based energy source; and finally cost. There was no "fuel" cost at all, the wind is free, and the initial capital cost, around €1 m per megawatt, was now starting to fall. So for a windy onshore site it could now be claimed that wind was the cheapest source of power.

Andrew's final slide was of a wind-powered road vehicle running straight into the wind, the result of a hobby activity of little practical relevance, but of great interest at least to those who did, or supervised, numerous projects on that very idea in the Department 25 years ago.

This very lively and entertaining lecture was followed by several questions. They concerned such things as:

| Contents | Next article >> |

| SOUE News Home |

Copyright © 2013 Society of Oxford University Engineers |

SOUE Home |